Abubuwan Bukatun Aikin

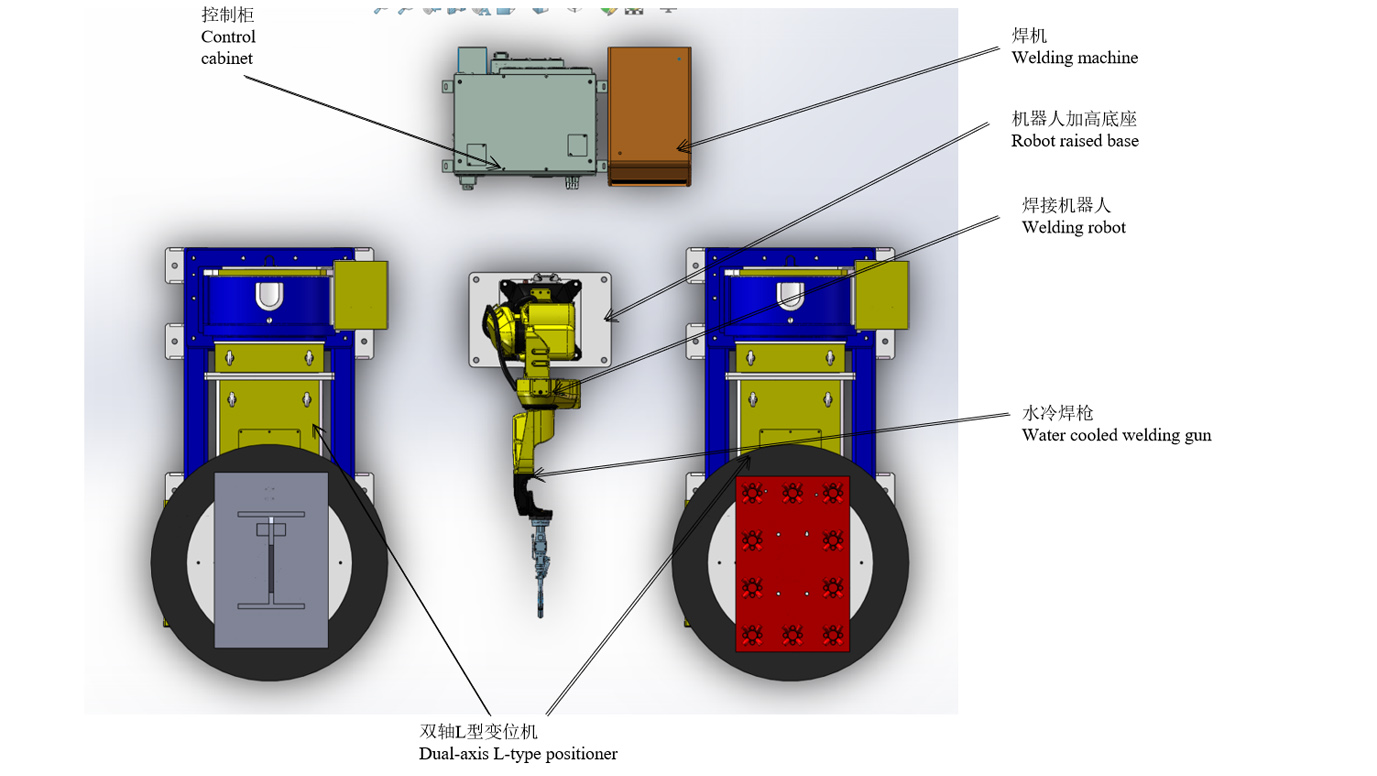

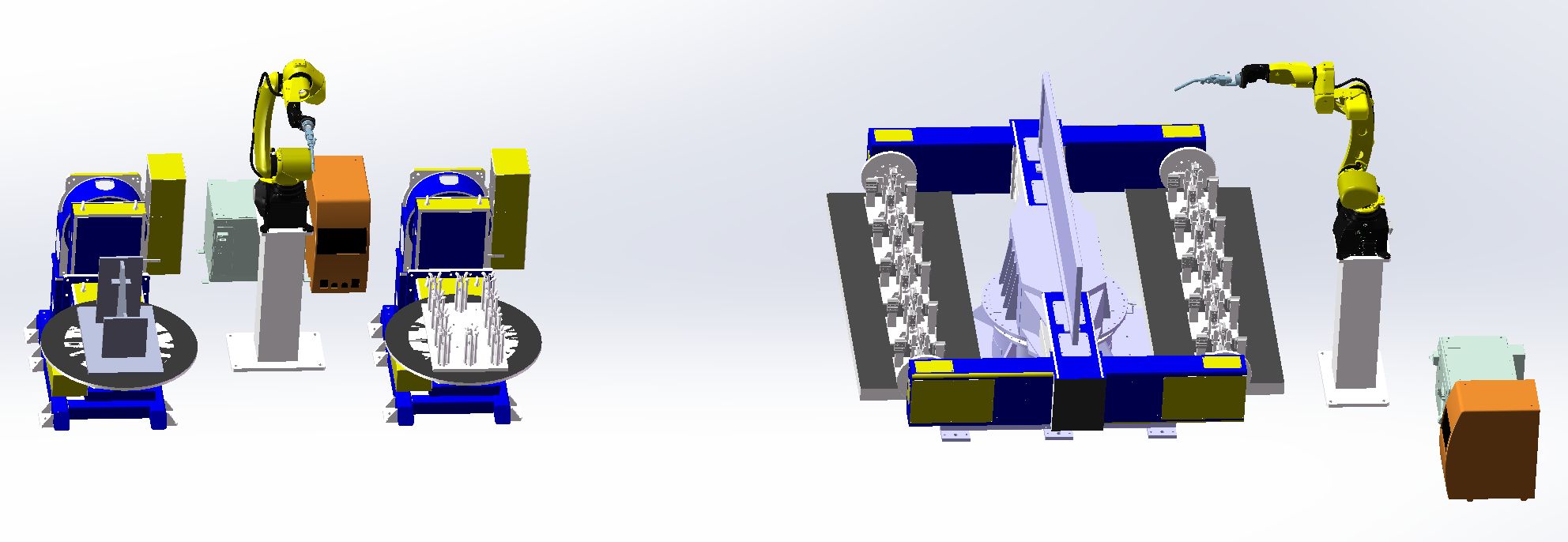

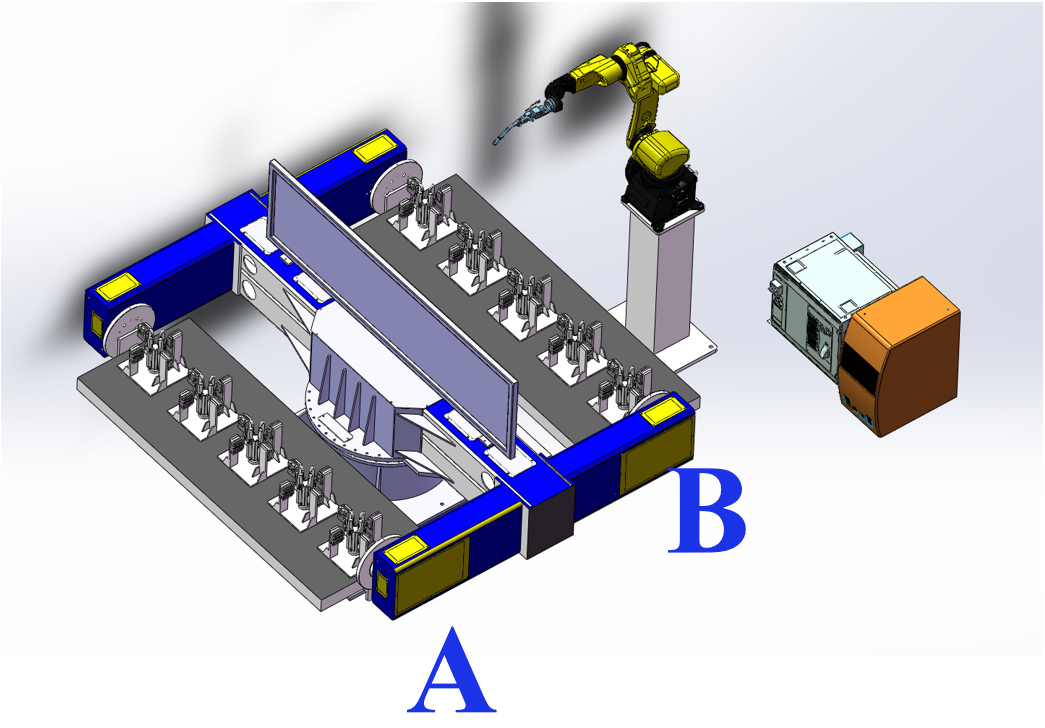

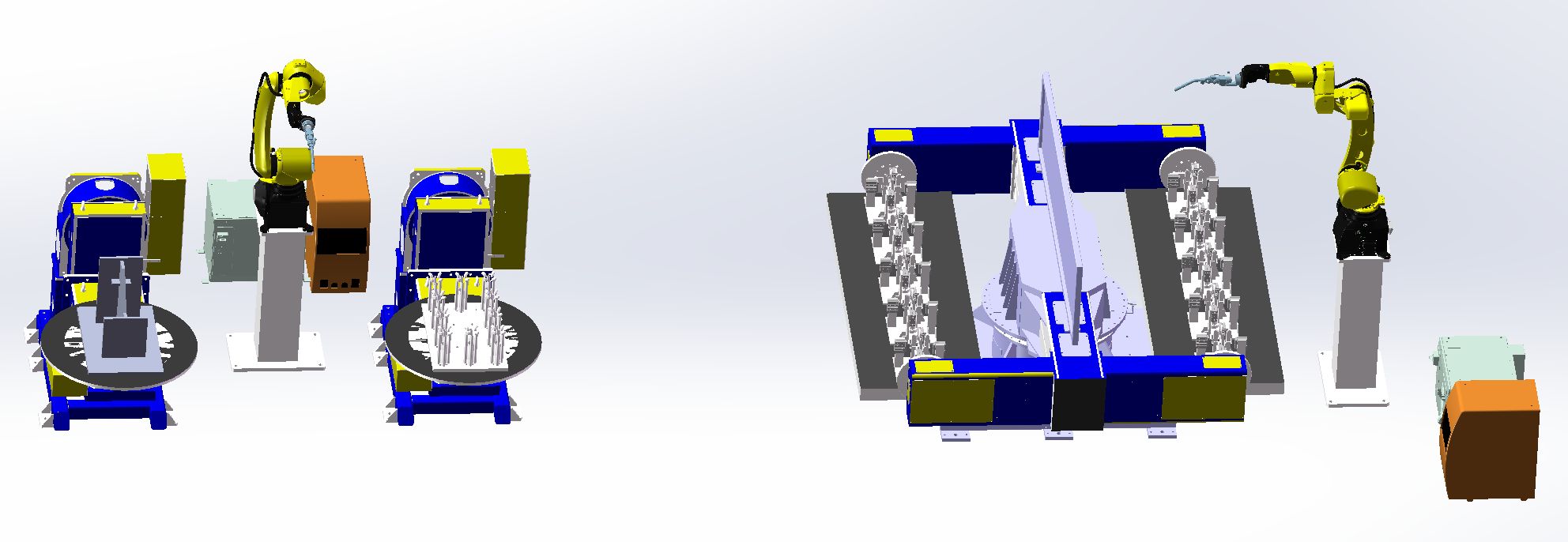

Gabaɗaya Layout&3D Model

Lura: Zane-zanen ƙirar ana amfani da shi ne kawai don kwatanta shimfidar wuri kuma baya wakiltar tsarin kayan aiki na zahiri. Za a ƙayyade ƙayyadaddun girman bisa ga yanayin wurin abokin ciniki.

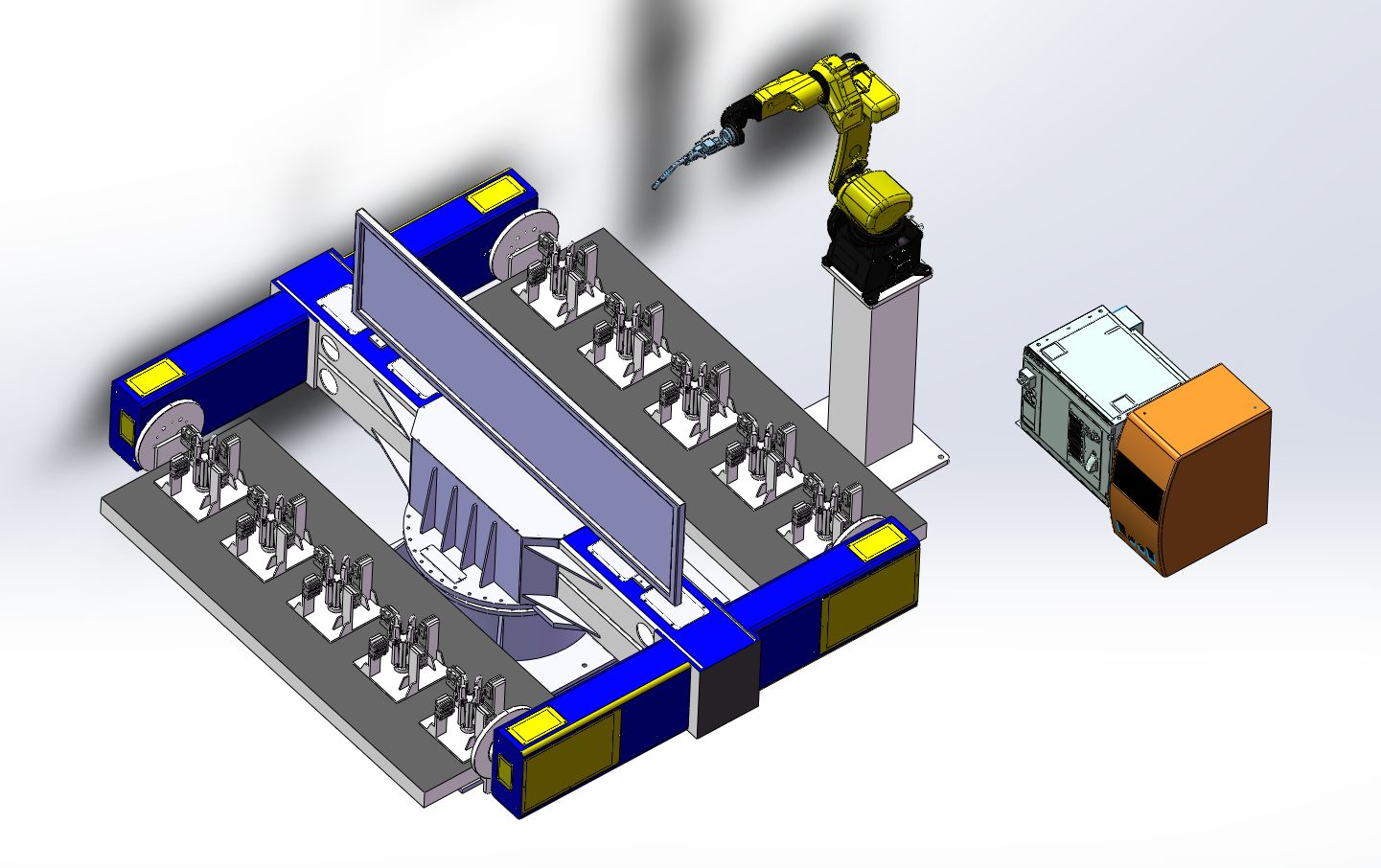

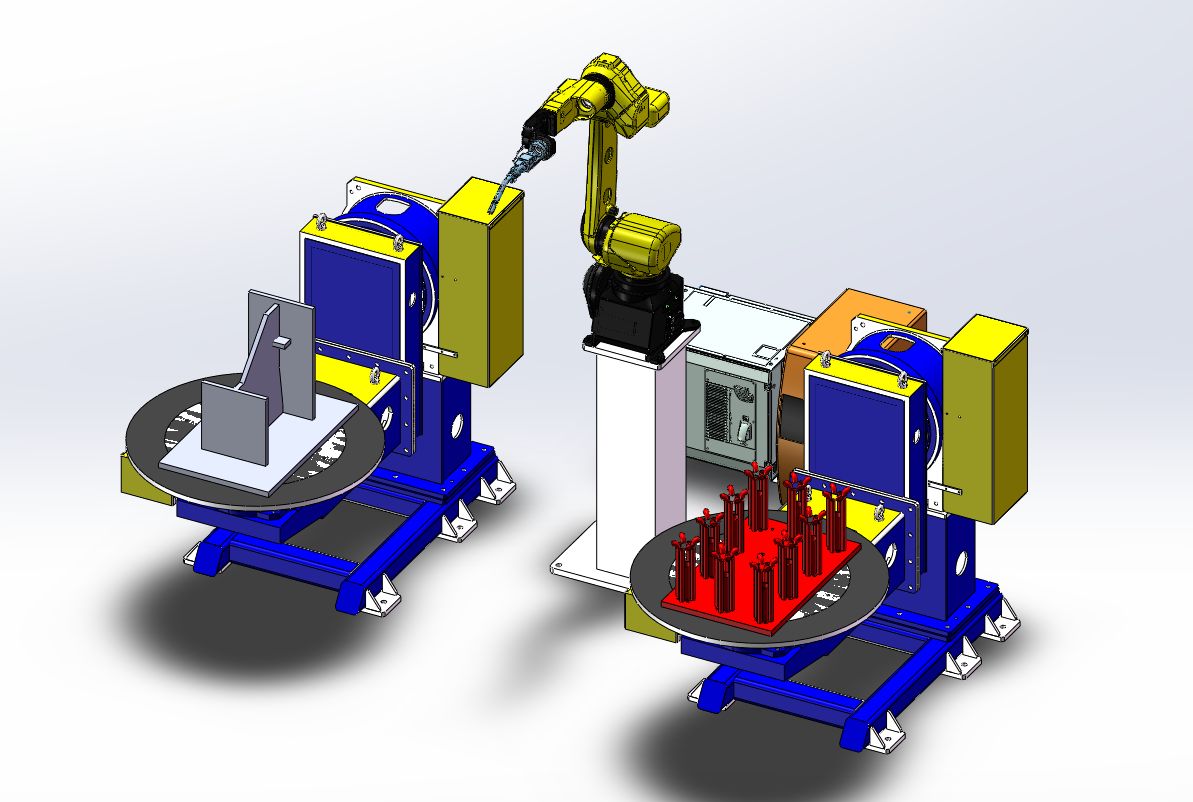

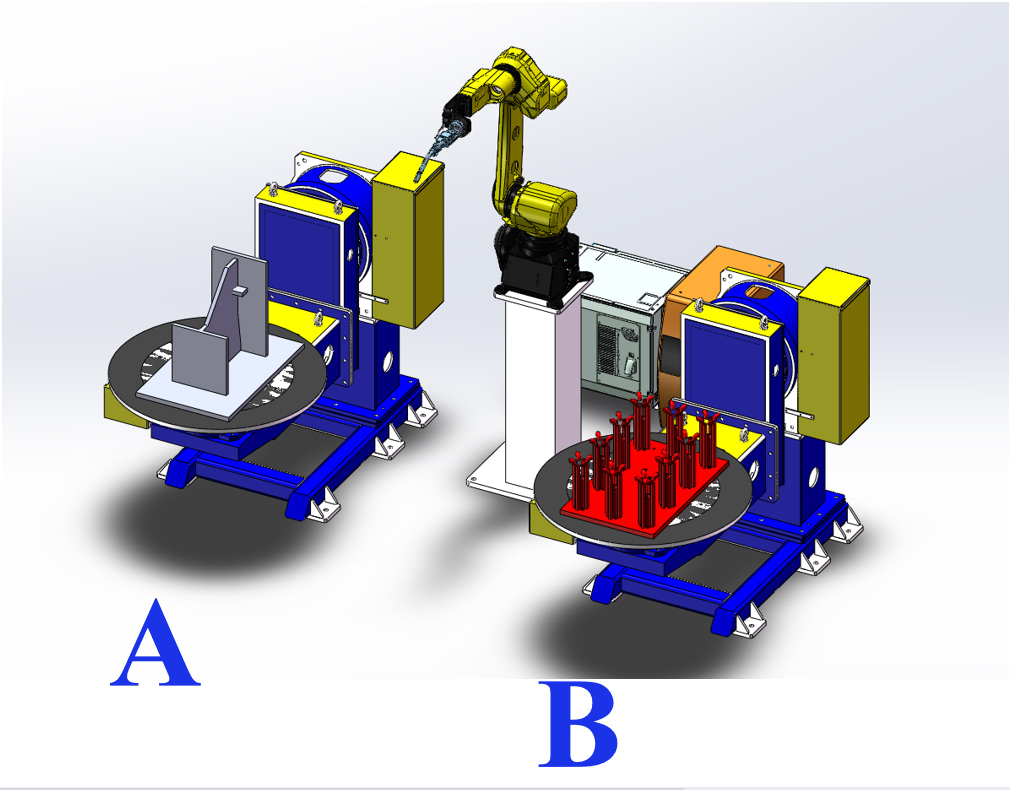

Zane na zahiri & ƙirar 3D

Zane na zahiri & ƙirar 3D

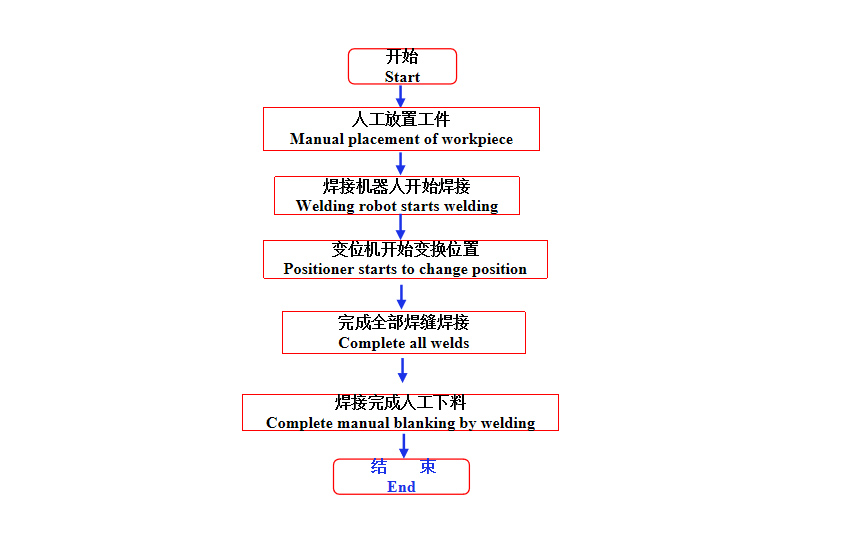

Gudun aiki

Sharuɗɗan aikin wurin aiki

(1) Da hannu sanya workpiece a cikin positioner kuma gyara shi bisa ga bukatun.

(2) Bayan an kunna duk na'urori kuma ba a nuna ƙararrawa ba, shirya don shigarwa.

(3) Mutum-mutumi ya tsaya a asalin aikin, kuma tsarin tafiyar da robot shine shirin samar da daidai.

Welding tsari na hannun riga subassembly

1. Sanya sassan hannun riga guda biyar da hannu a gefen A.

2. Komawa wurin aminci da hannu kuma fara maɓalli madaurin silinda don ƙara ƙarfin aiki.

3. Mai sakawa yana juyawa har sai robobin da ke gefen B ya fara walda.

4. Da hannu saukar da workpieces welded a gefe A, sa'an nan biyar sets na drum sassa.

5. Zagaya aikin hanyoyin haɗin da ke sama.

Lokacin walda don kowane saitin hannun riga shine 3min (ciki har da lokacin shigarwa), kuma lokacin walda na saiti 10 shine 30min.

Welding tsari na saka farantin taro + hannun riga taro

1. Shigar da farantin da aka riga aka nuna a kan madaidaicin nau'in L a gefen A.

2. Fara button robot waldi saka farantin taro (15min / saita). 3.

3. Shigar da sassa maras kyau na taron hannun hannu akan madaidaicin nau'in L a gefen B.

4. The robot ci gaba da weld da hannun riga taron bayan waldi da saka farantin taro (sleeve waldi for 10min + manual shigarwa na workpiece da robot tabo waldi na 5min)

5. Cire taron farantin da aka haɗa da hannu.

6. Manual walda na saka farantin taro (cire-tabo waldi-loading a cikin 15min)

7. Shigar da farantin da aka riga aka nuna a kan madaidaicin nau'in L a gefen A.

8. Cire taron welded hannun riga kuma shigar da kayan gyara

9. Zagaya aikin hanyoyin haɗin da ke sama.

Lokacin kammala walda na farantin da aka saka shine 15min + waldi lokacin kammala taron hannun riga shine 15min.

Jimlar lokaci 30min

Gabatarwar Na'urar Canjin Tong

Lokacin walda na robot a bugun da aka ambata a sama ya fi isa ba tare da tsayawa ba. Dangane da sa'o'i 8 a kowace rana da masu aiki guda biyu, fitar da majalisu biyu jimlar saiti 32 a kowace rana.

Don ƙara fitarwa:

Ana ƙara mutum-mutumi ɗaya zuwa madaidaicin axis uku a tashar ƙaramin hannun hannu kuma an canza shi zuwa waldawar injin ninki biyu. A lokaci guda kuma, tashar haɗaɗɗiyar faranti + hannun riga tana buƙatar ƙara saiti biyu na matsayi na nau'in L da saitin robot ɗaya. A rana ta awa 8 da ma'aikata uku, fitar da majalisu biyu jimlar saiti 64 a kowace rana.

Jerin Kayan aiki

| Abu | S/N | Suna | Qty | MAGANAR |

| Robots | 1 | RH06A3-1490 | 2 saiti | Chen Xuan ne ya bayar |

| 2 | Robot iko majalisar | 2 saiti | ||

| 3 | Robot tashe tushe | 2 saiti | ||

| 4 | Ruwa mai sanyaya bindigar walda | 2 saiti | ||

| Kayan aiki na gefe | 5 | Welding Power Source MAG-500 | 2 saiti | Chen Xuan ne ya bayar |

| 6 | Dual-axis L-type positioner | 2 saiti | ||

| 7 | Matsakaicin jujjuya a kwance-axis uku | 1 saiti | Chen Xuan ne ya bayar | |

| 8 | Daidaitawa | 1 saiti | ||

| 9 | Gun Cleaner | Saita | Na zaɓi | |

| 10 | Kayan aikin cire kura | 2 saiti | ||

| 11 | Katangar tsaro | 2 saiti | ||

| Sabis mai alaƙa | 12 | Shigarwa da ƙaddamarwa | abu 1 | |

| 13 | Marufi da sufuri | abu 1 | ||

| 14 | Koyarwar fasaha | abu 1 |

Ƙayyadaddun Fasaha

Ginin bindiga mai sanyaya ruwa a ciki

1) Kowace bindigar walda za ta bi ta hanyar aunawa ta ternary don tabbatar da daidaiton girman;

2) Sashin R na bindigar walda ana yin shi ne ta hanyar simintin simintin kakin zuma, wanda ba zai lalace ba saboda yawan zafin jiki da ake samu ta hanyar walda;

3) Ko da waldi gun karo tare da workpiece da tsayayye a lokacin aiki, waldi gun ba zai tanƙwara kuma babu sake gyara da ake bukata;

4) Inganta tasirin gyaran gas na garkuwa;

5) Daidaiton ganga guda ɗaya yana cikin 0.05;

6) Hoton don tunani ne kawai, kuma yana ƙarƙashin zaɓi na ƙarshe.

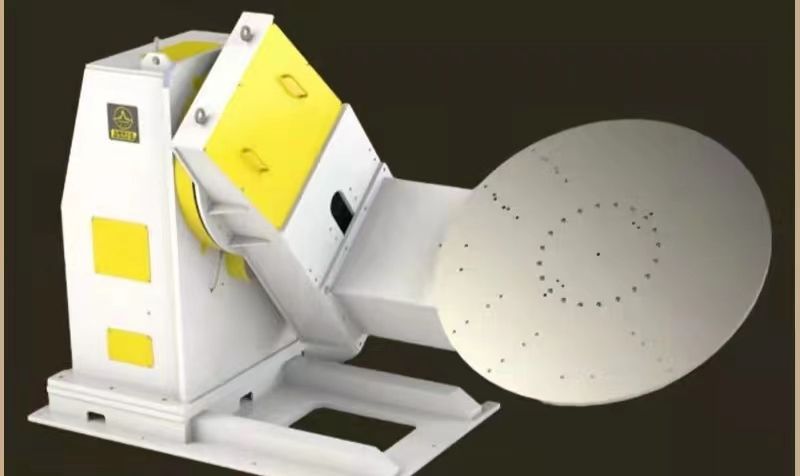

Dual-axis L-type positioner

Positioner ne na musamman waldi karin kayan aiki, wanda ya dace da walda matsuguni na Rotary aiki, don samun manufa machining matsayi da waldi gudun. Ana iya amfani da shi tare da manipulator da na'urar walda don samar da cibiyar walda ta atomatik, kuma ana iya amfani da ita don ƙaurawar aiki yayin aikin hannu. Ana ɗaukar fitarwa mai canzawa tare da injin mitoci masu canzawa don jujjuyawar benci, tare da ƙayyadaddun ƙa'idodin saurin gudu. Akwatin sarrafawa mai nisa na iya gane aikin nesa na workbench, kuma ana iya haɗa shi tare da manipulator da tsarin sarrafa injin walda don gane aikin haɗin gwiwa. Matsakaicin walda gabaɗaya ya ƙunshi na'urar jujjuyawar juyi da tsarin jujjuyawar benci. The workpiece gyarawa a kan workbench iya isa da ake bukata waldi da taro kwana ta hanyar dagawa, juya da juyi na workbench. A workbench yana jujjuya cikin ƙa'idar saurin mitar stepless mitar, wanda zai iya samun gamsasshen saurin walda.

Hotuna ne don tunani kawai, kuma yana ƙarƙashin ƙira ta ƙarshe.

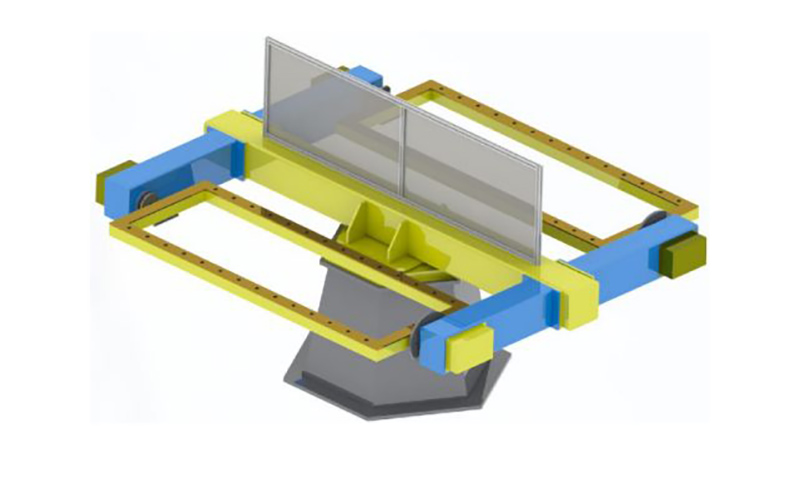

Matsakaicin jujjuya a kwance-axis uku

1) Uku-axis kwance Rotary positioner ne yafi hada da wani m kafaffen tushe, Rotary spindle akwatin da wutsiya akwatin, waldi frame, servo motor da daidaitaccen rage, conductive inji, m murfin da lantarki kula da tsarin, da dai sauransu.

2) Ta hanyar daidaita injinan servo daban-daban, ana iya sarrafa mai sakawa ta hanyar mai koyar da robot ko akwatin aiki na waje;

3) Ana samun walƙiya da ake buƙata da kusurwar taro ta hanyar juya kayan aikin da aka gyara akan benci;

4) Juyi na workbench ana sarrafa shi ta hanyar motar servo, wanda zai iya cimma saurin walƙiya mai kyau;

5) Hotunan don tunani ne kawai, kuma yana ƙarƙashin ƙira ta ƙarshe;

walda wutar lantarki

Ya dace da splicing, lapping, kusurwar haɗin gwiwa, tube farantin butt hadin gwiwa, intersection line dangane da sauran hadin gwiwa siffofin, kuma zai iya gane duk matsayi waldi.

Tsaro da aminci

Na'urar waldawa da mai ba da waya suna sanye take da fiye da na yanzu, fiye da ƙarfin lantarki da kariya mai zafi. Sun wuce gwajin aikin EMC da lantarki da ake buƙata ta daidaitattun GB/T 15579 na ƙasa, kuma sun wuce takaddun shaida na 3C don tabbatar da aminci da amincin amfani.

Kiyaye makamashi da kare muhalli

Lokacin gano iskar gas, lokacin samar da iskar gas gaba da lokacin samar da iskar gas ana daidaita su don tabbatar da ingantaccen amfani da iskar gas. Lokacin da na'urar walda ta kunna, idan ba ta shiga yanayin walda a cikin mintuna 2 ba (lokacin daidaitacce), za ta shiga yanayin barci kai tsaye. Kashe fanka kuma rage yawan kuzari.

Hoton don tunani ne kawai, kuma yana ƙarƙashin zaɓi na ƙarshe.

walda wutar lantarki

Tsabtace bindiga da na'urar fesa mai na silicone da na'urar yankan waya

1) Silicone man spraying na'urar na gun tsaftacewa tashar rungumi dabi'ar biyu bututun ƙarfe don giciye fesa, sabõda haka, silicone man iya isa ciki surface na waldi tocilan bututun ƙarfe mafi alhẽri da kuma tabbatar da cewa waldi slag ba zai manne da bututun ƙarfe.

2) An tsara na'urorin tsabtace bindiga da na'urorin feshin mai na silicone a wuri guda, kuma robot na iya kammala aikin fesa mai na silicone da tsabtace bindiga tare da aiki ɗaya kawai.

3) Game da sarrafawa, tsaftacewar bindiga da na'urar fesa mai siliki kawai yana buƙatar siginar farawa, kuma ana iya farawa bisa ga ƙayyadaddun jerin ayyuka.

4) Na'urar yankan waya tana ɗaukar tsari mai tayar da kai na bindigar walda, wanda ke kawar da buƙatar yin amfani da bawul ɗin solenoid don sarrafa shi kuma yana sauƙaƙa haɓakar wutar lantarki.

5) Za a iya shigar da na'urar yankan waya daban ko sanya shi a kan tsabtace bindiga da na'urar fesa mai na silicone don samar da na'ura mai haɗaka, wanda ba wai kawai adana sararin samaniya ba, amma kuma ya sa tsari da sarrafa hanyar gas mai sauƙi.

6) Hoton don tunani ne kawai, kuma yana ƙarƙashin zaɓi na ƙarshe.

Katangar tsaro

1. Saita shingen kariya, kofofin tsaro ko matakan tsaro, makullai masu aminci da sauran na'urori, da gudanar da kariya ta ma'amala mai mahimmanci.

2. Za a saita ƙofar tsaro a daidai wurin shingen kariya. Duk kofofin za a sanye su da maɓallan tsaro da maɓalli, maɓallin sake saiti da maɓallin dakatar da gaggawa.

3. Ƙofar aminci tana haɗuwa tare da tsarin ta hanyar kulle kulle (canzawa). Lokacin da aka buɗe ƙofar aminci ba bisa ka'ida ba, tsarin yana dakatar da aiki kuma yana ba da ƙararrawa.

4. Matakan kariyar tsaro suna ba da garantin amincin ma'aikata da kayan aiki ta hanyar hardware da software.

5. Za a iya samar da shingen aminci ta Party A kanta. Ana ba da shawarar yin amfani da walda mai inganci mai inganci da gasa fentin gargaɗin rawaya a saman.

Tsarin Kula da Lantarki

1. Ya haɗa da tsarin sarrafawa da sadarwar sigina tsakanin kayan aiki, ciki har da na'urori masu auna firikwensin, igiyoyi, ramummuka, masu sauyawa, da dai sauransu;

2. An tsara naúrar atomatik tare da hasken ƙararrawa mai launi uku. Yayin aiki na al'ada, hasken launi uku yana nuna kore; idan naúrar ta gaza, hasken launi uku zai nuna jajayen ƙararrawa a cikin lokaci;

3. Akwai maɓallan tsayawa na gaggawa akan ma'ajin sarrafa mutum-mutumi da akwatin koyarwa. A cikin yanayin gaggawa, ana iya danna maɓallin dakatar da gaggawa don gane dakatarwar gaggawa na tsarin kuma aika siginar ƙararrawa a lokaci guda;

4. Za a iya haɗa nau'o'in shirye-shiryen aikace-aikacen ta hanyar na'urar koyarwa, yawancin aikace-aikace za a iya haɗa su, wanda zai iya biyan bukatun haɓaka samfurin da sababbin samfurori;

5. Duk alamun dakatarwar gaggawa na duk tsarin sarrafawa da siginar ƙulla aminci tsakanin kayan aiki da na'urori masu amfani da mutum-mutumi an haɗa su da tsarin tsaro kuma an kulle su ta hanyar tsarin kulawa;

6. Tsarin sarrafawa yana gane haɗin siginar tsakanin kayan aiki irin su robot, kaya mai kaya, gripper da kayan aikin machining.

7. Machine kayan aiki tsarin bukatar gane siginar musayar tare da robot tsarin.

Yanayin aiki (wanda Jam'iyyar A ta samar)

| Tushen wutan lantarki | Ƙarfin wutar lantarki: uku-lokaci hudu-waya AC380V ± 10%, ƙarfin lantarki kewayon ± 10%, mita: 50Hz; Ana buƙatar samar da wutar lantarki na majalisar sarrafa robot don samar da wutar lantarki mai zaman kanta; Dole ne majalisar kula da robot ɗin ta kasance ƙasa tare da juriya na ƙasa ƙasa da 10Ω; Ingantacciyar nisa tsakanin samar da wutar lantarki da majalisar sarrafa wutar lantarki ta robot yana tsakanin mita 5. |

| Tushen iska | Dole ne a tace iska da aka matsa don cire danshi da ƙazanta, kuma matsi na fitarwa bayan wucewa ta uku zai zama 0.5 ~ 0.8Mpa; Ingantacciyar nisa tsakanin tushen iska da jikin mutum-mutumi yana tsakanin mita 5. |

| Foundation | Za a yi amfani da bene na siminti na al'ada na taron bita na Party A don magani, kuma za a gyara tushe na shigarwa na kowane kayan aiki zuwa ƙasa tare da ƙusoshin fadada; Ƙarfin ƙira: 210 kg / cm 2; Kauri na kankare: fiye da 150 mm; Rashin daidaituwa na tushe: ƙasa da ± 3mm. |

| Yanayin Muhalli | Yanayin yanayi: 0 ~ 45 ° C; Dangantakar zafi: 20% ~ 75% RH (babu tari); Haɗawar girgiza: ƙasa da 0.5G |

| Sauran | Ka guji iskar gas da ruwa masu ƙonewa da lalata, kuma kada a watsa mai, ruwa, ƙura, da sauransu; Ka nisanci tushen hayaniyar lantarki. |