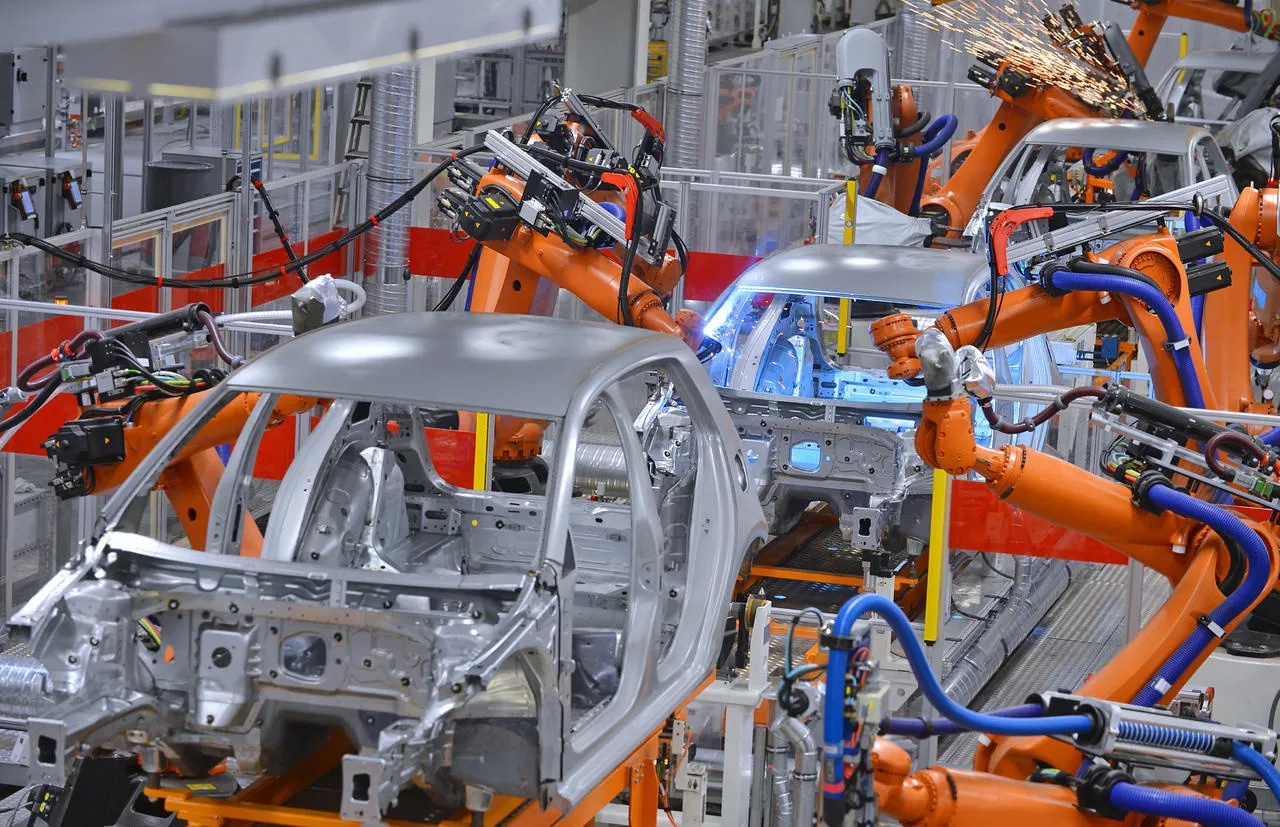

Rarraba Case – Motar Firam ɗin Welding Project

Lamarin da zan raba muku yau shine aikin walda firam ɗin mota. A cikin wannan aikin, ana amfani da mutum-mutumi na walda mai nauyi 6-axis da tsarin taimakonsa gaba ɗaya. Ana kammala aikin waldawar firam ɗin ta amfani da bin diddigin kabu na Laser, sarrafa madaidaicin matsayi, tsarin tsabtace hayaki da ƙura, da software na shirye-shiryen layi, da sauransu.

Kalubalen aikin

1. Hadaddiyar Tsare-tsaren Tafarki

Matsala: 3D masu lankwasa na sararin samaniya a cikin welds ɗin firam ɗin suna buƙatar daidaitawar fitilu marasa karo.

Magani: Simulators na zahiri ta amfani da software na shirye-shirye na layi (misali, RobotStudio) ingantattun kusurwoyin wuta, cimma daidaiton hanyar 98% ba tare da koyar da gyare-gyaren lanƙwasa ba.

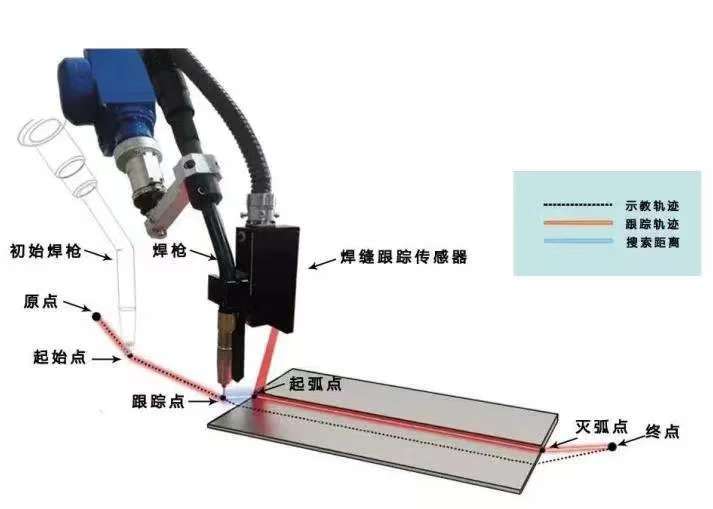

2. Daidaita-Sensor Multi-Sensor

Batu: Walda na bakin ciki ya haifar da nakasu, yana buƙatar gyare-gyaren siga na ainihin lokaci.

Ci gaba: Laser tracking + Arc Sensing Fusion fasahar cimma±0.2mm daidaitaccen gyaran kabu.

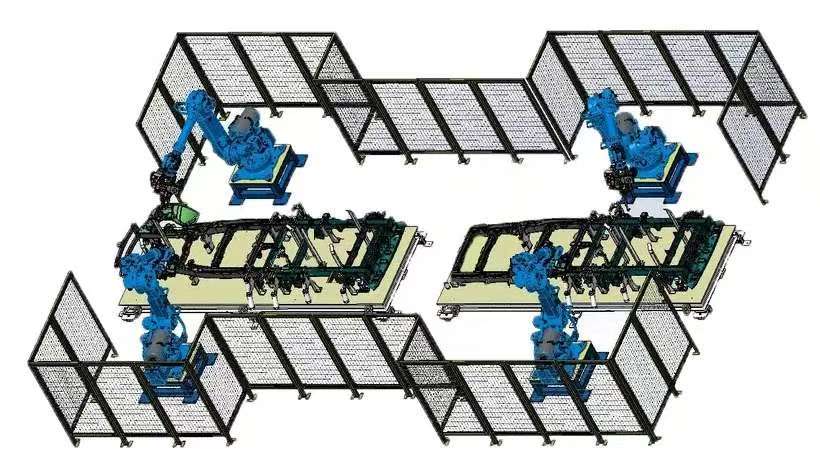

3. Tsarin Tsarin Tsaro

Kalubale: Mahimman dabaru don haɗa shingen tsaro da labulen haske tare da sa hannun hannu (misali, sake yin aiki).

Ƙirƙira: Yanayin-biyu (auto/manual) ƙa'idodin aminci sun rage lokacin canza yanayin zuwa <3 seconds.

Mahimman bayanai na aikin

1. Algorithm Adaptive Welding

Matsakaicin ciyarwar waya mai ƙarfi ta hanyar amsawar-ƙarfin wutar lantarki na yanzu ya rage bambancin shigar walda daga ± 0.5mm zuwa ± 0.15mm.

2. Modular Fixture Design

Canje-canje masu sauri sun kunna sauyawa tsakanin ƙirar firam 12, yanke lokacin saitin daga mintuna 45 zuwa 8.

3. Haɗin Twin Digital

Saka idanu mai nisa ta hanyar dandamalin tagwayen dijital an annabta gazawar (misali, rufewar bututun ƙarfe), haɓaka tasirin kayan aiki gabaɗaya (OEE) zuwa 89%.

Lokacin aikawa: Afrilu-19-2025